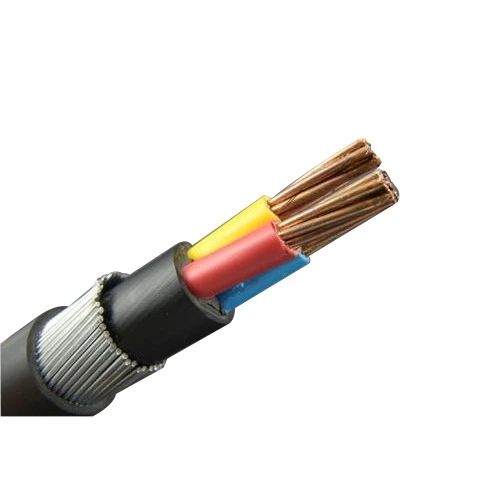

Electrolyte Grade Aluminium Conductor of IS: 8130 / 1984,

Type ‘A’ PVC Compound Insulation of IS: 5831 / 1984,

ST-1 PVC Compound Sheath of IS: 5831 / 1984

Steel Strip Armouring of IS: 3975 / 1979,

Armoured / Unarmoured PVC Insulated PVC Sheathed Heavy Duty Cables for working voltage from 650 to 1100 Volts. Other types of Power / Control Cables or Copper Conductor cables with change in H R Insulation or F R Sheathing can also be provided.

DOWNLOAD CATALOGUE

When we talk about electrical wiring and power distribution, it is essential to know that choosing the right power cable makes all the difference. It is necessary for safety, durability, and performance.

At Swadeshi Cables, we have been in this industry for years: making high-quality and durable power cables for different industries - commercial, industrial and residential. We aren’t just a brand anymore, but a symbol of trust in every sector.

Types of insulations and types of different cables, they can be slightly confusing topics, indeed. So, we’ve come up with our own simplified guide to help you make better decisions according to your requirements.

Power cables are used to transfer electricity from one point to another. They are used in a variety of setups: home, commercial and industrial.

They are built in such a way that they can handle high voltage and current, offering great insulation and added protection during electricity transmission.

They are better than simple powers because they have that added insulation to them. Moreover, power cables are made up of a group of multiple insulated wires: this is why they’re so strong and durable. As opposed to simple wires, they’re used where power demand is high.

Power cables can be used in a wide variety of places across a wide range of industries. Some of the places where they are widely used are:

And a lot more places. Basically, anywhere where a large amount of consistent power is needed.

Insulation is one of the most important components of power cables. They make sure that the wire you’re using is safe and reliable. Choosing the cable with right insulation or covering, thus, becomes extremely critical.

If the insulation used is not compatible with the usage, then there could be potential hazards. To avoid them, let’s learn about the two types of insulations: PVC insulated cables and XLPE insulated cables.

PVC stands for Polyvinyl Chloride. These are amongst the most commonly used and popular types of insulated cables. Here’s why they stand out:

Although power cable are widely used, there are some things you need to keep in mind while using them: The maximum continuous operating temperature of PCV insulated cables is around 70 degree celsius. If exceeded, there could be problems.

So, these cables are used where there is minimal machinery involved, and the cables are not exposed to high temperatures.

XLPE stands for Cross-linked Polyethylene. These types of insulated cables are suitable for environments where both power and voltage demand is high.

Here’s why they are much more reliable and durable:

The XLPE insulated cables are perfect for environments where voltage requirement is high, or heavy machinery and other power appliances are in use. Basically, they’re in for the heavy usage.

They’re also widely used in underground installations, where electricity needs to be transferred a large distance from under the ground.

If you’re still wondering about the right kind of insulation to go with for your power cable, here’s a simple breakdown for you:

What’s your voltage requirement?

If high, go with XLPE. If it’s low, go with PVC.

Where do you plan to install the cables?

If it’s indoors or in less harsh environments, go with PVC. If not, then go with XLPE.

Do you require high temperature resistance, like up to 90 degree celsius?

If yes, XLPE is the best one to go with.

Do you need flexible power cables for tight spaces?

If yes, PVC should be your choice.

To sum up, choose PVC insulation for easy, indoor, budget-friendly usage. If you’re leaning more towards industrial, high-voltage, heavy usage, then go with XLPE insulation.

The type of core configuration that you choose depends widely on your electrical installation requirement. There are two types of power cables available in the market: Single Core Cables and Multi Core Cables.

Let’s understand what they are, what they do, and which one should you choose, in detail:

They are made of a single conductor, placed within an insulating sheath. They are basically used in places where high-voltage power needs to be transmitted over large distances. Let’s look at their key features:

They’re widely used in the following places: internal panel wiring, power distribution, battery connections, inverters etc.

Essentially, single core power cables are perfect for environments where there is a need of high voltage and high current, and straightforward routing of the current is required. For more diverse, compact, and multiple circuit or power arrangement, we have multi core cables.

These cables are made up of multiple insulated conductors, which are bundled together and placed within a single outer sheath.

They are perfect for transmitting different types of signals: power, data, audio. Mostly used in places where voltage requirement is low to medium.

Here are their key features:

At Swadeshi cables, we make sure that we offer the highest quality of multi core power cables, which are highly used in places such as:

Residential and office wiring where multiple circuits are present, industrial machinery, control panels, audio and video equipment, etc.

To put together simple words, multi core power cables are used when multiple signals and power circuits need to run together, mostly in compact and organised spaces. These cables prove to be highly efficient in these cases because of their flexibility.

With our several years of experience, we have made a reputable name in the cable industry over the past decades.

Our company uses eco‑friendly manufacturing processes, recyclable materials, and all of this has helped us in becoming the most-trusted power cables brand.

Today, our cables are used in multiple sectors of India, like Airports, Metro systems, Railways, etc.

What’s more? We even create customised cables according to the clients’ needs. All our products are backed by certifications like ISO 9001:2015, so you can always be assured that you buy from a company that follows all the safety regulations.

In this blog, we’ve covered everything people usually want to know about power cables, and we hope that this has helped you to make your own informed decision.

Click on the Download Catalogue link to explore the latest Swadeshi Cables product range.

Follow Us on Instagram

Like Us on Facebook page

Type: PVC / XLPE insulated cables conforming to IS:1554-I / IS:7098-I, BS:6346, IEC:60502, BS:5467, BS:7846

Sizes : Single Core Cables 16 Sqmm to 1000 Sqmm Multicore 4 Sqmm to 400 Sqmm

Voltage Rating: 1.1 kV

Conductor : Stranded / Solid / Circular shaped as per class-2 of IS:8130

Material : Aluminum / Copper

Insulation : PVC/XLPE/FRLSH PVC / FRLSH XLPE

Inner sheath :PVC IS:1554 (PART-1) AND for XLPE Cables IS: 7098 (Part-1)

Armouring : Galvanized steel Round wires / Flat Strip or Aluminum Wire /Flat Strip