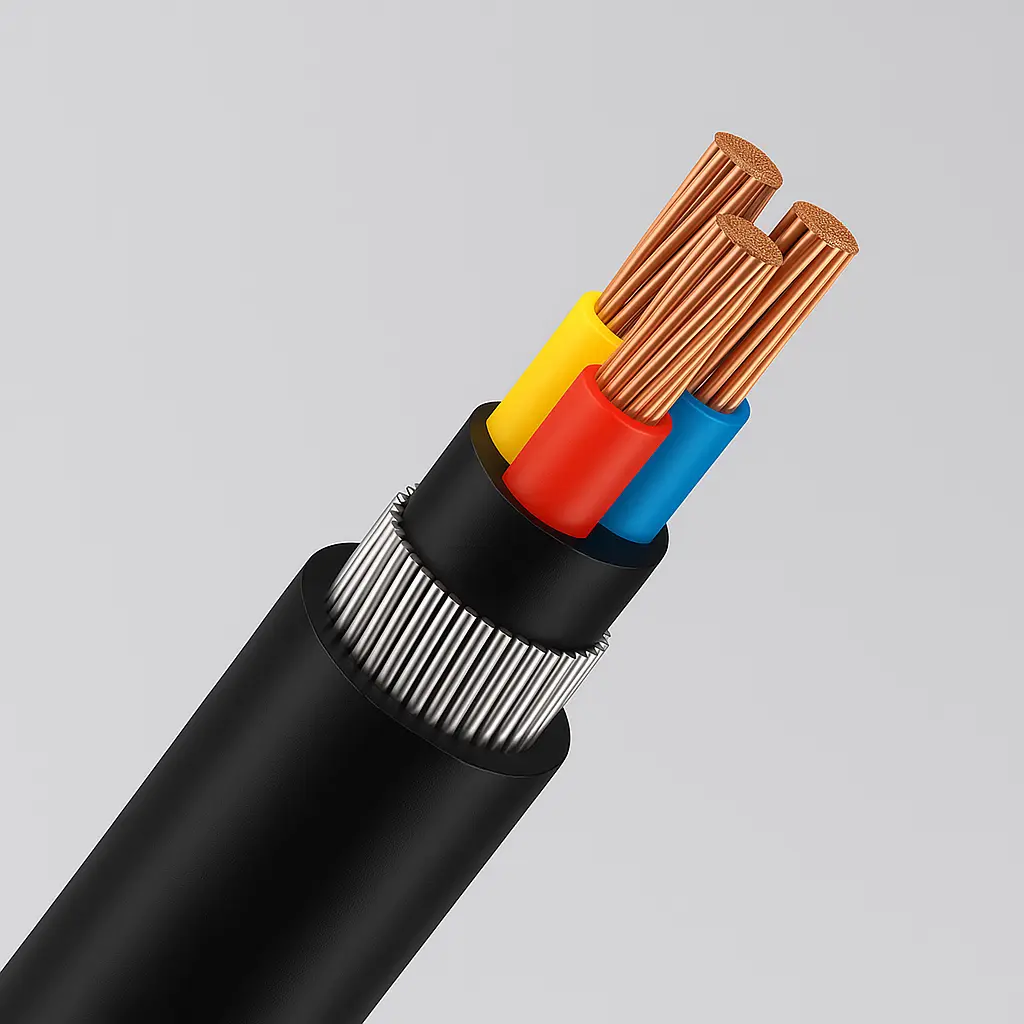

Electrolyte Grade Annealed bare copper / option – Tinned of IS : 8130 / 1984,

PVC Type A of IS: 5831/ OPTION : HR PVC ( Type -C of IS -5831)

Nominal insulation thickness – 0.80mm Cores identification : Up to 5 Cores by colour coding & more than 5 Cores : By colour coding / Nos. printing on cores as per IS: 1554/7098 pt-1

INNER SHEATH : Extruded PVC as per IS :1554/7098 PT-1

ARMOURING : Single layer of Galvanized steel Round wires / Flat Strips as applicable

OUTER SHEATH PVC TYPE ST-1 OF IS 5831‘— OPTIONS PVC TYPE ST-2 OF IS 5831/ FR TYPE/ FRLS TYPE COLOUR OF OUTER SHEATH BLACK OPTIONS any other colour as per requirement

DOWNLOAD CATALOGUE

Signal-carrying electrical cables are called control cables. They are commonly found in sectors like manufacturing, transportation, automation, and power generation.

They work by transmitting the control signals rather than power, like in power cables. Control cables are highly useful for the effectiveness and safety of machine operation. They carry low-voltage electrical signals that communicate when machines are meant to start, stop, slow down, speed up, or switch modes.

Without them, machines and systems would be unable to respond to instructions appropriately, and there would be problems like delays, and potential hazards.

They are designed to be tough and strong. They contain layers of insulation and protection to them, to avoid any signal loss, electrical noise, and physical damage.

Despite their similarities in looks, control cables and power cables serve very different purposes. Large volumes of electricity are transported between locations with the help of power cables. They are highly useful in supplying electricity to buildings, machinery, etc. These cables are designed to handle high voltage and current.

Whereas, very low electrical signals are carried by control cables. They aren't used for powering machines. Rather, they help in controlling them by sending instructions or signals. In short, power cables provide energy. Communication through signals is done with the help of control cables.

LT means for low tension. Electrical systems that work with low voltage, typically up to 1100 volts, use LT control cables. These types of cables are very easy to use, install, and can easily fit in small spaces.

LT control cables are suitable for short-distance or small control circuits. They are used in both industrial and residential applications. They are available in unarmoured and armoured cables to provide a level of protection which suits your installation needs.

These cables are used in:

However, there are some precautions one must take, like avoiding the overloading of cable even if voltage is low, and using proper insulation in moist or risky areas.

In many types of control cables, galvanized steel round wires function as a protective outer layer. In this way, they shield the cable from physical damage, compression, wetness, and even rodents. Thus, they are well suited for outdoor or underground use.

The zinc coating on the steel will not rust and therefore allows the cable to be useful longer.

Some things important to know when using galvanised steel round wires are:

However, some precautions to take care of are:

Some important features of XLPE insulated cables: XLPE stands for Cross Linked Polyethylene. It is a type of strong plastic material used to cover the wires inside a cable. Unlike regular plastic, XLPE can handle heat better and does not break or damage easily.

This kind of insulation is used in both control and power cables, especially in places where the environment is hot and humid, or a place where chemicals may be present.

Some important features of XLPE insulated cables:

Here are some precautions you can take while using XLPE insulated cables: Do not bend or pull the cable too tightly during installation as it can damage the wire. Always avoid using it near open flames or welding machines.

Flexible control cables are created to bend or move without any issue. Flexible cables are perfect for machines that have a lot of constant movements like lifts, moving arms, or automated doors.

These cables are made with many small copper wires that are twisted together. This arrangement makes these cables flexible and easy to move, unlike normal rigid cables that may break if they are bent too much.

At Swadeshi Cables, we make cables that are flexible and easy to install. They are usable even in compact spaces where other regular cables may fail to work or fit.

However, here are some things you should consider while using them. Avoid pulling or stretching the cable more than necessary. Avoid sharp bends and do not exceed the recommended curve limit, as this can overburden the cable.

Choosing the right cable can feel difficult at first, especially since they come in many types. However, if you're aware of the application for the cable and the requirement of what it will handle, it will make the choice easier.

Cables are manufactured to handle different voltages. For basic control systems, LT (Low Tension) cables would be sufficient in nearly all cases. They will work well in any system under 1100 volts. However, if you are using larger equipment, you should look for cables with a higher rating.

When the cable is going to be moved often like in elevators or gates, use a flexible control cable. They are constructed of finely stranded copper and will be flexible without causing any breakage or damage.

3. Where will the power cable be used?

Consider where the cable will be, inside or outside? Also consider if it is going to be in constant contact with water, dust or chemicals?

In such harsh environments, use cables with a Galvanized Steel protection. In areas where there will be heat or moisture use cables with XLPE insulation for added protection. If used outside or under ground ensure the cable is weather and water resistant.

Verify that the cable you are purchasing follows the appropriate certifications and standards is important. Cables from companies like Swadeshi Cables are thoroughly tested and adhere to all safety standards. This means that you can trust the cables to provide you with high-quality and safe performance.

You can choose the right cable for your needs with confidence by following these easy steps, which will save you future time, money, and hassle.

For the past 45 years, Swadeshi Cables has earned a strong reputation for providing cable options that are reliable and high performance all over India.

Swadeshi’s cables are manufactured using the latest technology and are tested under proper environments. The company is ISO 9001:2015 certified and adheres to standard BIS standards IS 694, IS 7098, and IS 1554. Swadeshi Cables is trusted by the biggest key sectors, such as metro rail, defense, highways, and power projects, which speaks of the trust that people have put into us.

With our expertise in control cables, we hope this blog helped you in learning more about them and their different types.

You can also get information about Power Cable

Follow Us on Instagram

Like Us on Facebook page

Type: PVC / XLPE insulated cables conforming to IS:1554-I / IS:7098-I, BS:6346, IEC:60502, BS:5467, BS:7846and Customer specific requirements

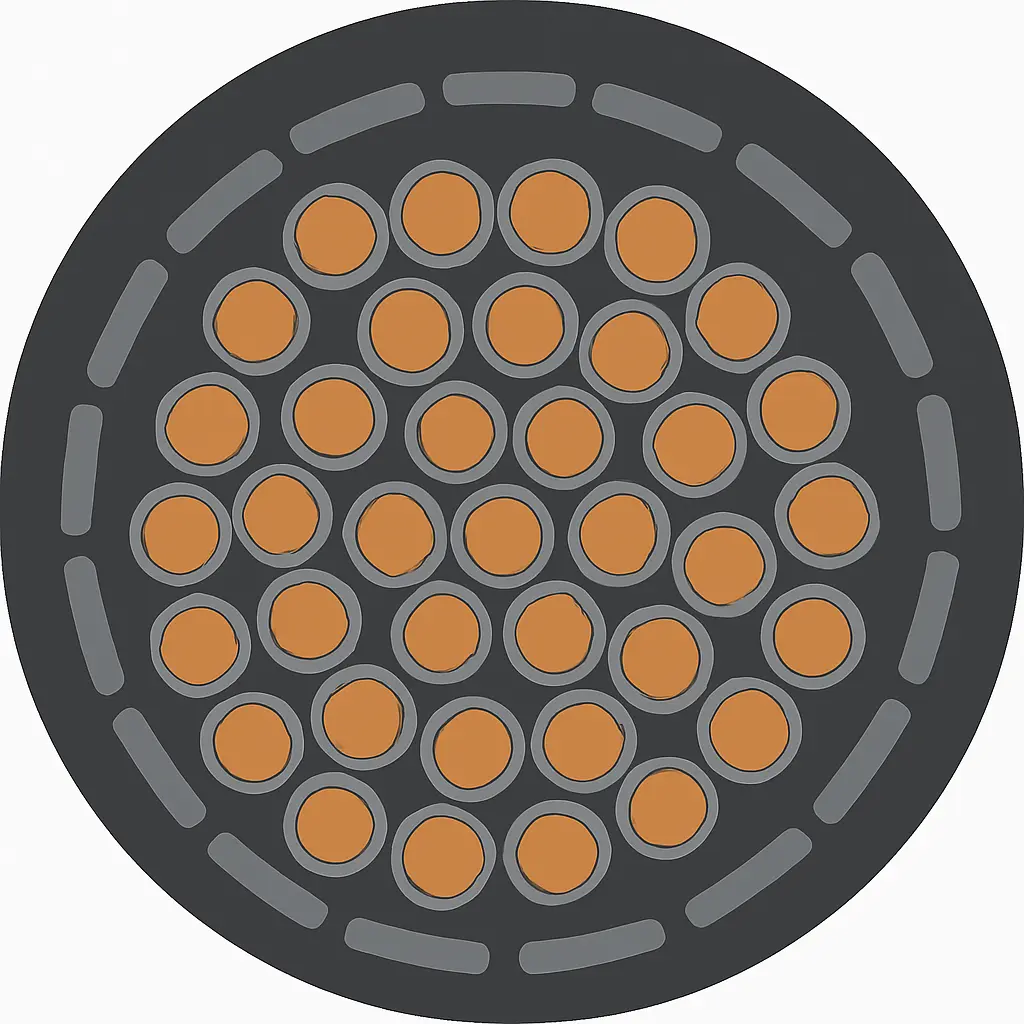

1.50 /2.50 Sqmm upto 37 Core

Voltage Rating: 1.1 kV

Conductor – Stranded / Solid / Plain /Tinned Circular shaped as per class-2 of IS:8130

Material – Annealed electrolytic copper conductor

Insulation : PVC/XLPE/FRLSH PVC / FRLSH XLPE

Inner sheath :PVC IS:1554 (PART-1) AND for XLPE Cables IS: 7098 (Part-1)

Armouring : Galvanized steel Round wires / Flat Strip or Aluminum Wire /Flat Strip